Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 28, 2026

Automated Flavor Compounding Facility

In the hyper-competitive global food and beverage landscape, “flavor” is often discussed in the context of marketing and consumer delight. However, for the professional manufacturer, flavor is a rigid technical specification—a complex chemical matrix that must remain identical across millions of units. When this matrix deviates, the results are catastrophic: expensive rework, diminished shelf life, and the looming threat of a product recall.

Maintaining consistent flavor quality is not merely a goal of the Quality Assurance (QA) department; it is a fundamental pillar of Good Manufacturing Practices (GMP) and a prerequisite for maintaining Global Food Safety Initiative (GFSI) certifications. This article provides an authoritative analysis of the technical, operational, and economic drivers of flavor consistency and outlines a roadmap for achieving “Right First Time” manufacturing.

To solve the problem of inconsistency, we must first define what it is. In technical terms, flavor drift is the measurable deviation of a product’s organoleptic profile from its established “Gold Standard” or “Target Control.”

A typical liquid flavor is not a single substance but a symphony of volatile organic compounds (VOCs) including esters, aldehydes, ketones, alcohols, and terpenes, often dissolved in a carrier solvent like propylene glycol, ethanol, or vegetable oil.

For example, a standard “Natural Strawberry Flavor” may contain over 50 individual chemical constituents. If the concentration of just one key aromatic—such as ethyl methylphenylglycidate—varies by even a few parts per million (ppm), the entire profile can shift from “fresh fruit” to “medicinal” or “candy-like.” This level of sensitivity is why flavor is often the most volatile variable in the production process.

“Rework” is often a “hidden” cost in manufacturing because it is frequently absorbed into general labor or “shrinkage” metrics. However, from a technical standpoint, flavor-related rework is among the most difficult to execute successfully.

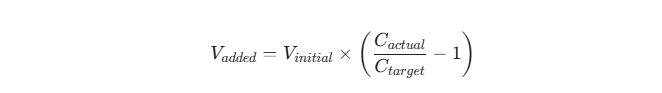

When a 10,000-gallon batch of beverage is flagged for being “off-profile,” the production manager faces a mathematical nightmare. If the batch is over-flavored (too high in intensity), the solution is dilution.

Where V is volume and C is concentration. While the formula is simple, the execution is not. Adding 2,000 gallons of water/base to a 10,000-gallon batch requires:

Reworked products often sit in holding tanks longer than fresh batches. During this time, “flavor scalping” occurs—where the aroma compounds are absorbed by the gaskets, seals, and tank walls. This means that by the time a “fixed” batch is ready for bottling, the flavor profile may have shifted again, leading to a second round of rework or a decision to scrap the entire batch.

While rework hurts the internal P&L, a recall destroys external brand equity and invites regulatory scrutiny from agencies like the FDA (USA), EFSA (EU), or SAMR (China).

It is a common misconception that flavor recalls are only about taste. In reality, flavor consistency is a proxy for process control. A deviation in flavor often signals a deeper systemic failure:

According to a 20-year analysis of FDA data, processing issues—including manufacturing errors and mislabeling—account for approximately 9% of all food and beverage recalls (ResearchGate, 2024). A Class I recall, where there is a “reasonable probability” of health issues, can result in legal settlements and mandatory plant shutdowns.

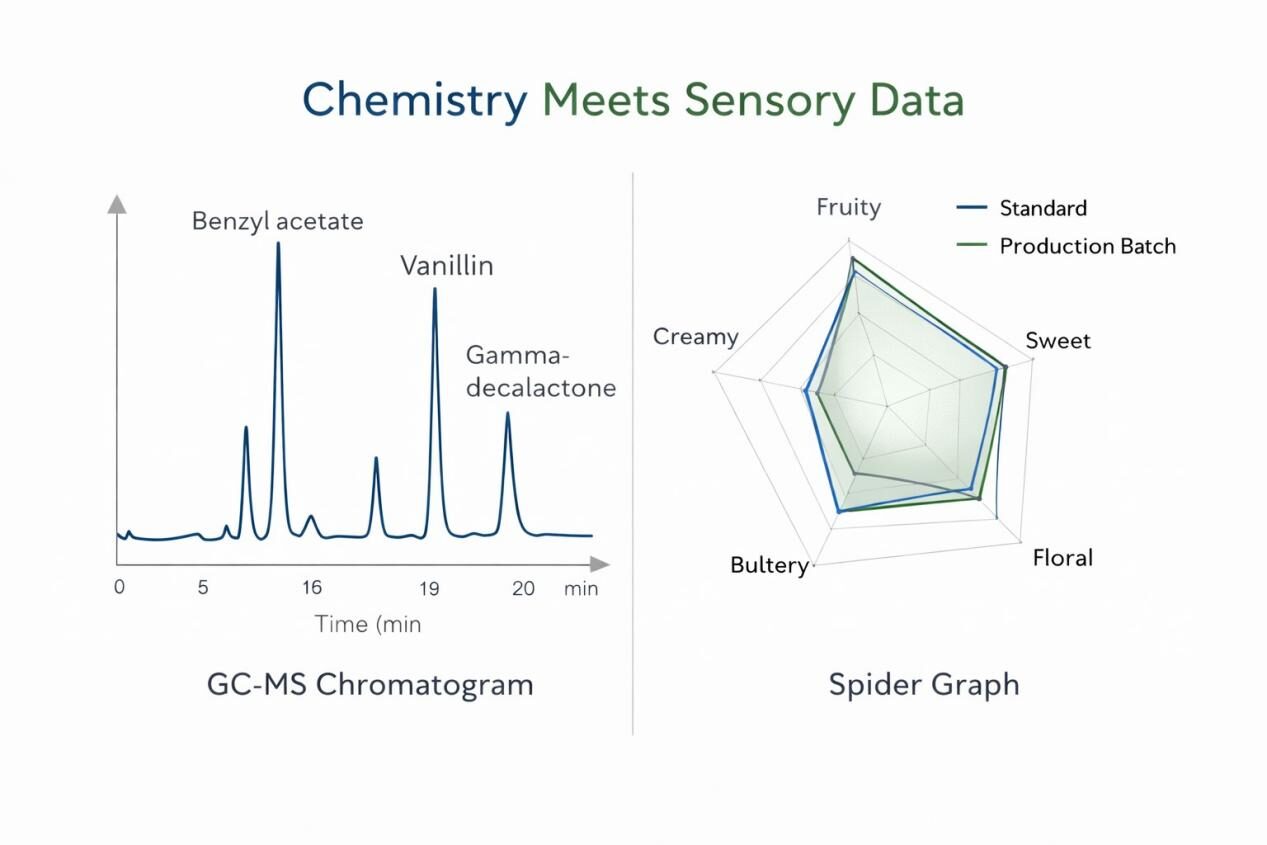

To eliminate human error, modern manufacturers are moving toward “Objective Quality Gates.” This involves using analytical chemistry to quantify flavor before it ever reaches the production floor.

GC-MS is the gold standard for flavor analysis. By vaporizing a flavor sample and passing it through a capillary column, we can separate every individual molecule and identify it based on its mass-to-charge ratio.

For non-volatile components, such as the “heat” in a chili flavor (capsaicinoids) or the bitterness in tea (catechins), HPLC provides precise quantification. This ensures that the functional aspects of the flavor—not just the aroma—remain consistent

Chemistry and Sensory Data Comparison

Despite the power of GC-MS, the human nose remains one of the most sensitive analytical tools on earth, capable of detecting certain pyrazines at parts-per-trillion levels—concentrations so low that most machines miss them.

A professional flavor manufacturer doesn’t just “taste” a product; they evaluate it using Descriptive Analysis.

Consistency is psychological. Consumers associate flavor with safety. If a consumer opens their favorite brand of orange juice and it tastes slightly “metallic” or “too floral,” their brain flags it as “spoiled,” even if the product is microbiologically safe. This “Neophobia” (fear of new/different tastes) leads to immediate brand switching and negative social media sentiment.

As a flavor manufacturer, our job is to engineer “Process-Resilient” flavors. This means the flavor must be designed to survive the customer’s specific manufacturing environment.

In high-heat applications like baking or extrusion, top-notes evaporate. We utilize Spray Drying or Melt Injection to encapsulate flavor droplets in a protective matrix (usually maltodextrin or gum arabic). This “Timed Release” ensures the flavor is only released when the consumer chews the product, maintaining consistency even if the production oven runs 5 ℃ hotter than usual.

Many flavors are pH-sensitive. An anthocyanin-based natural color/flavor might be a vibrant red at pH 3.0 but turn a sickly grey at pH 4.5. We buffer our flavor systems to ensure that minor fluctuations in the customer’s water source or base ingredients do not trigger a chemical shift.

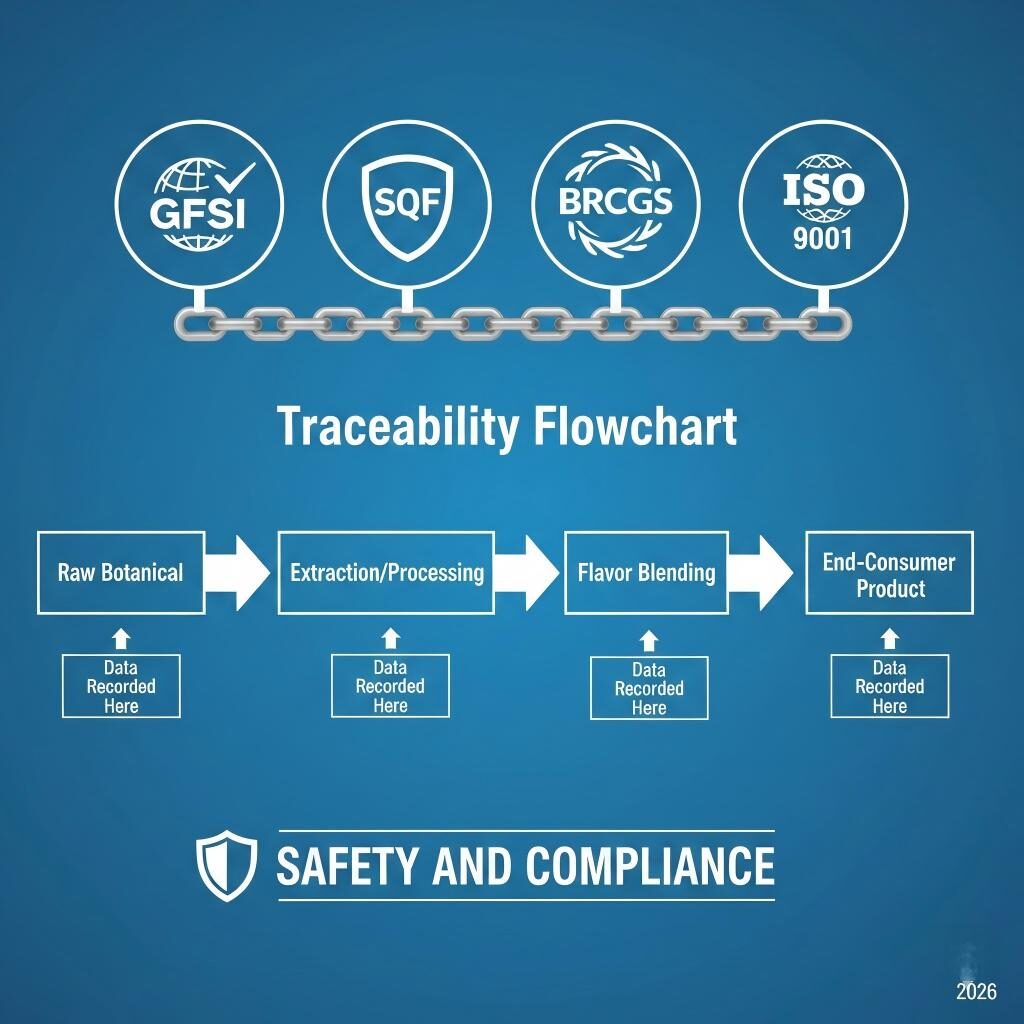

Flavor consistency is a product of supply chain discipline. Sourcing flavors from a GFSI-certified (SQF/BRC) facility is the first line of defense against recalls.

In the event of a suspected quality issue, a manufacturer must be able to trace every gram of flavor back to its raw material components within 2 hours. This requires integrated ERP systems that link the flavor lot number to:

Safety & Traceability Infographic

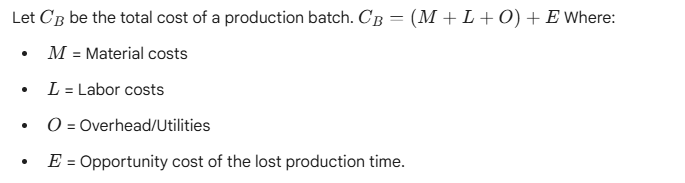

To persuade executive leadership to invest in higher-quality flavor systems, one must speak the language of Return on Investment (ROI).

If a batch requires rework, the cost doubles for labor and overhead, and the opportunity cost E becomes exponential as it delays subsequent orders. A flavor system that costs 10% more but reduces rework by 50% pays for itself within the first quarter of production.

A recall costs an average of $10 million in direct costs (Registrar Corp, 2025). If the use of a stabilized, standardized flavor system reduces the risk of a “Processing Error” recall by even 1%, it acts as a highly effective insurance policy for the company’s valuation.

The industry is moving toward Industry 4.0, where flavor consistency is monitored in real-time during the mixing process.

Near-Infrared (NIR) sensors are being integrated directly into mixing tanks. These sensors can detect the concentration of flavor volatiles in real-time. If the concentration drops below the target, the PLC automatically doses more flavor, ensuring that every bottle filled is identical to the first.

Artificial Intelligence is now being used to predict how a flavor will age. By inputting the chemical structure of a flavor and the packaging type, AI can predict the “Flavor Decay Curve,” allowing manufacturers to adjust their “use-by” dates or fortification levels to ensure the consumer always gets a consistent experience.

The reduction of rework and the elimination of recalls are not achieved through luck; they are achieved through technical rigor and the selection of the right flavor partner.

A professional flavor manufacturer does more than sell a “tasty” liquid. They provide:

When flavor is consistent, the production line runs smoothly, the brand remains untarnished, and the consumer’s trust is reinforced with every sip or bite.

Shared Moments Lifestyle

Is your production team constantly “adjusting” batches to meet flavor targets? Are you concerned that your current flavor profile won’t survive a transition to a new processing method (e.g., moving from Hot-Fill to Aseptic)?

Let’s solve the consistency equation together.

Our team of flavor chemists and application technologists is ready to conduct a Flavor Stability Audit for your product line.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.