The New Imperative: Flavor and Safety Intersect

In the global food and beverage industry, there is no compromise more critical than consumer safety. For the millions of individuals worldwide who live with food allergies, a single, minuscule exposure to an allergen can trigger a severe, life-threatening reaction. For manufacturers, a single instance of allergen cross-contamination can lead to a massive product recall, severe brand damage, and significant legal and financial consequences.

In this high-stakes environment, every ingredient and every step of the supply chain must be meticulously managed. Flavors, with their complex formulations and often intricate supply chains, represent a key vulnerability that can be easily overlooked. A flavor may not contain an allergen by design, but its journey from raw material to final product can create a risk of cross-contamination if not managed with a zero-tolerance approach.

Sourcing allergen-free food-grade flavors is not just a regulatory checklist item; it is a critical, proactive step toward a comprehensive food safety strategy. It requires a meticulous, scientific, and transparent approach from the flavor manufacturer, built on a foundation of rigorous testing, robust documentation, and a culture of total accountability. This comprehensive technical guide will serve as a blueprint, detailing the scientific, procedural, and strategic steps required for manufacturers to confidently minimize allergen risk and build products that are both delicious and safe for all consumers.

Before we can build a solution, we must fully comprehend the gravity of the problem. Allergen risk is a profound issue that impacts public health, corporate responsibility, and brand reputation.

Food allergies are a growing global health crisis. In the United States alone, it is estimated that 32 million people have food allergies, with rates steadily increasing among children. A person’s immune system mistakenly identifies a harmless food protein as a threat, triggering a range of symptoms from mild rashes to severe anaphylaxis, a rapid and potentially fatal reaction that can close airways.

Regulatory bodies around the world have identified a set of common allergens that are responsible for the majority of allergic reactions. In the United States, the Food and Drug Administration (FDA) identifies the “Big 8”:

In recent years, countries have added new allergens to their lists, such as sesame in the U.S. and celery, mustard, and lupin in the European Union. Manufacturers have a legal and moral obligation to manage these allergens and ensure accurate labeling. The Food Allergy Research & Education (FARE) organization provides extensive resources on the prevalence and management of these allergens, underscoring the severity of the issue (Reference 1: FARE, 2024, “Food Allergy Facts and Statistics”).

A flavor is a complex mixture of many components, each with its own supply chain. Even if a flavor is designed to be free of a specific allergen, the risk of cross-contamination during manufacturing is real. This can occur in several ways:

A single allergen-related recall can have devastating consequences. The financial costs are immense, including recall expenses, legal fees, lost sales, and the potential for regulatory fines. The reputational damage is often even more severe. A single misstep can erode consumer trust, a hard-earned asset that can take years to rebuild. A 2023 report in a leading food science journal highlighted that allergen-related recalls are one of the most common and expensive types of food safety incidents, emphasizing the need for robust preventative measures (Reference 2: J. Food Sci., 2023, “Analysis of Food Safety Recalls: Trends and Prevention Strategies”).

A reputable flavor manufacturer must treat allergen management as an integral part of its core operations. It’s not an afterthought; it’s a foundational principle.

A comprehensive AMP is the cornerstone of allergen-free flavor production. It is a multi-faceted system designed to prevent, detect, and control allergen risks.

A flavor is only as reliable as its documentation. A reputable flavor manufacturer maintains a meticulous record-keeping system that provides an unbroken chain of custody for every ingredient.

Documentation and protocols are vital, but they must be backed by science. Analytical testing provides the objective proof that a flavor is truly allergen-free.

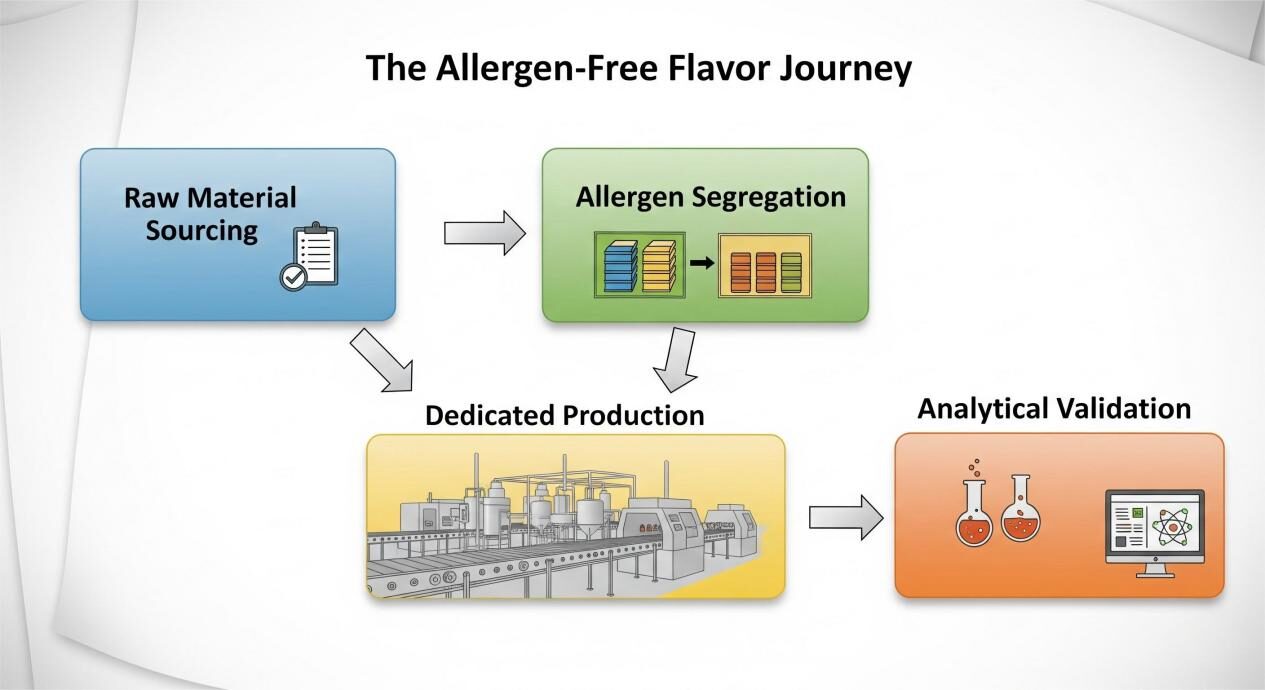

The Allergen-Free Flavor Journey

For a food manufacturer, ensuring the allergen-free status of its products requires a collaborative, strategic partnership with its flavor supplier. Here is a practical blueprint for how to select and work with a flavor partner to minimize allergen risk.

Before even considering a flavor, a manufacturer must vet the supplier’s commitment to allergen management.

The allergen declaration is the key legal and scientific document that transfers the responsibility for allergen management from the flavor supplier to the manufacturer. It is a legally binding document that states whether an allergen is present in the flavor or if there is a risk of cross-contamination. The manufacturer must then use this declaration to ensure proper labeling on their final product.

Once an allergen-free flavor arrives at your facility, the responsibility for maintaining its status falls on you.

Even after taking every precaution, the final product must be tested.

A proactive approach to sourcing allergen-free flavors is not just a matter of compliance; it is a strategic business decision that provides a powerful market advantage.

In an era of increasing consumer awareness, a brand’s reputation for safety and transparency is a powerful asset. By going above and beyond to minimize allergen risk, a brand builds invaluable consumer trust and loyalty. A single, transparent recall can even be turned into a positive by demonstrating a commitment to public safety.

The market for allergen-free products is growing at an incredible rate. By offering certified allergen-free products, a manufacturer can tap into a huge and underserved market segment. A 2024 report from Euromonitor International noted that the global allergen-free market is expanding at a compound annual growth rate (CAGR) of over 8%, with a transparent supply chain being a key driver of consumer choice (Reference 4: Euromonitor International, 2024, “Global Allergen-Free Market Trends”).

A robust allergen management plan protects a company from legal action and costly regulatory fines. It is a proactive step that demonstrates due diligence and a commitment to protecting public health. This level of diligence can be a key factor in avoiding punitive damages in the event of an incident.

Beyond the legal and commercial considerations, minimizing allergen risk is a moral and ethical obligation. It is a commitment to creating a safe food supply for all consumers, including those who are most vulnerable.

The Unbreakable Promise: Safe and Delicious

Minimizing allergen risk requires a comprehensive, zero-tolerance approach. It is a shared responsibility between the flavor manufacturer and the food manufacturer, built on a foundation of trust, transparency, and scientific rigor.

By forging a partnership with a flavor supplier that has a robust Allergen Management Program and a culture of total accountability, a manufacturer can de-risk their supply chain, protect their brand, and, most importantly, create products that are safe for everyone to enjoy. The future of food manufacturing belongs to those who prioritize safety and are willing to invest in the processes and partnerships required to deliver on that promise.

Keywords: allergen-free flavors, food allergies, food safety, allergen management

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 18, 2025

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.